Personal Home Page | Business Home Page | Resume

Ham Radio Projects Page | Computer Projects Page | Telesaver Projects Page | Project Chronology Page

Projects

or... wandering around the house, finding stuff that any normal person would have thrown out decades ago.

Take a walk down memory lane with me!

Many of these photos were taken in 2010 -- so the subjects don't look quite as nice as when they were built (:>).

Earliest

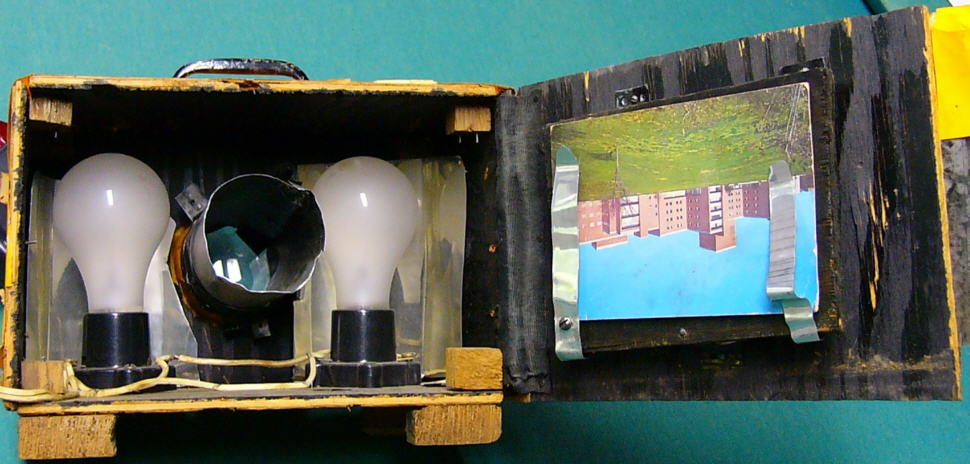

The earliest thing I can recall constructing was this opaque projector. I seem to remember being in the third grade, which would put it in 1963:

I found it in The Boy Electrician (below, page 371). The postcard inside is from June 1960, but maybe the card was old? My big brother thinks I was in first grade, but I can't imagine I really built it as a six year old.

It used two 100 watt lightbulbs and it got quite hot, even with the airholes at the top.

Commercial opaque projectors use a reflecting mirror to re-invert the image, so postcards (which it was designed for) had to be placed upside down,

and writing of course came out backwards. The projected image at the right is barely visible because my digital camera won't let me expose it long enough.

Not worth pulling out my old 35 mm SLR and develop real film!

An Idiot Box from some time in the 1960's: all it does is flash neon lamps. It's just three sets of relaxation oscillators made up purely of neon lamps, resistors, and capacitors.

Originally it used high voltage "B" batteries, but later I changed it to run off of the 120 VAC powerline.

I remember building this crystal radio in 1966:

Most of the parts have since disappeared, but it had an RF filter cap and a germanium diode (plus headphones). I'm not so old that I had to actually use a galena crystal with a cat's whisker!

I ran about a 50 foot wire from a second story window out to the backyard, and could pick up quite a few Baltimore AM stations.

Most of the parts have since disappeared, but it had an RF filter cap and a germanium diode (plus headphones). I'm not so old that I had to actually use a galena crystal with a cat's whisker!

I ran about a 50 foot wire from a second story window out to the backyard, and could pick up quite a few Baltimore AM stations.

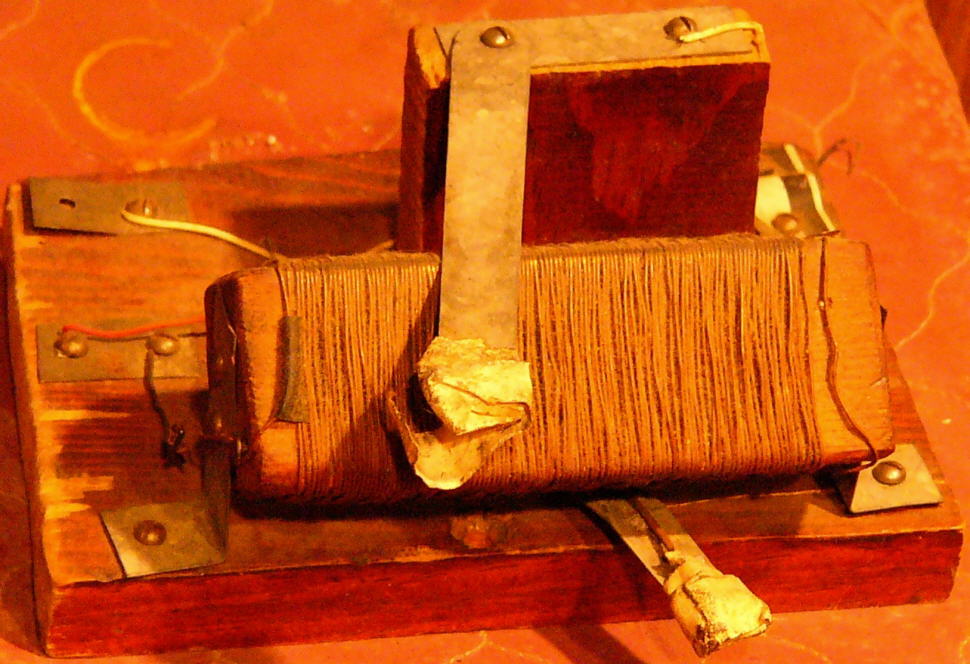

Other early projects: I built lots of stuff from Alfred P. Morgan's The Boy Electrician which I found in the library. A pdf of the book is here. I definitely built the microphone which is shown on page 175, but it wasn't quite like he shows it: I cut open two D batteries and removed the center carbon post (did a lot of that). Mounted them horizontally on the top of a cigar box, and laid a length of mechanical pencil graphite across the two posts. Then just put a battery and headphones in series with the contraption. I remember showing it in fifth grade, so that would be 1965.

I built the transformer shown in page 226. It seems crazy, because in the 1960's you wouldn't necessarily find the kinds of stores Morgan wrote about originally in 1913! But I found a sheet metal shop within walking distance, and the guy cut up hundreds of rectangular pieces for me. Couldn't have cost much as I was a little kid. Somehow found the copper wire, too. After building that one transformer, I decided I'd just get ready-made ones in the future.

Built many electromagnets (remember the large cylindrical 1.5 volt batteries with thumbscrew connecting

I did make a "bullhorn" which was a transistor amplifier wired to a speaker. I was definitely not impressed with the loudness, it was probably 100-200 milliwatts.

I had an intercom system on several floors of the house, probably when 11-12 years old.

Speaking of transistors, I struggled to understand them. All the books said you put current in the base-emitter junctions, and you got amplification at the base-collector pins.

I don't know how many transistors (they were all germanium in those days) I blew out in the 1960's, because I put a battery directly between the base and emitter (properly forward biasing it) and a DC motor at the base-collector;

I expected the motor to turn faster than without the transistor. Never happened. Eventually I learned the difference between power generation and control modulation!

ElectroChemistry:

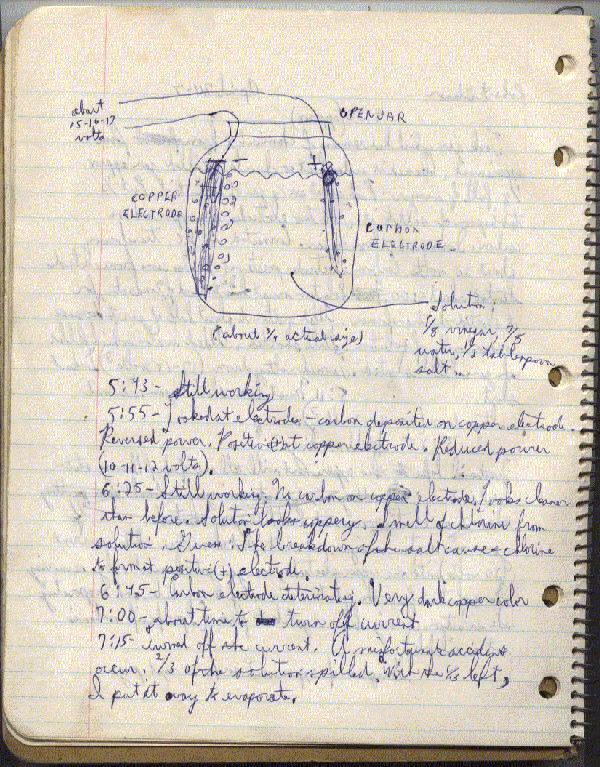

I seem to have been fascinated with breaking down aqueous molecules with electrolysis. I have a spiral notebook with entries dated April 7, 1967 through February 24, 1968 -- 72 handwritten pages in all. I filled gallon glass jugs with hydrogen, oxygen, chlorine, and who knows what other gases. You know the hydrogen test of putting a match under a small inverted test tube and getting a crack or popping sound from the combustion? I did that with gallon glass bottles and got a big (BIG) wooof! and lived to tell with no mishaps... mishaps... mishaps

Moonshine

This doesn't really belong in this section, but it's chemistry. In Drew Wolfe WA3KLK's high school chemistry class, we fermented various fruits and distilled the mash into wine. But I double-distilled (maybe triple?) mine! The result was probably near 100% ethyl alcohol. "Teach" advised us not to sample our wares, we were aware of potential serious health issues. But we were high school kids! Are you kidding me? I did take one sample (back then) and found it to be quite potent. I was already wearing eyeglasses and didn't become any more blind. This is the actual booze.

Yes, yes, I know -- you don't have to tell me. The fact that I still have this proves that I'm certifiably crazy!

Plumbing

Originally I had an old large pressure tank, and lots of salt and neutralizer equipment for my well, all from the original construction in 1966.

In 1992 I removed the neutralizer and salt equipment, and installed the neutralizer (tan, above left).

Also added the whole-house water filter (blue device to the right of the neutralizer). I still have a heck of a time getting compression fittings to completely seal,

always afraid if I tighten any more it's going to strip the threads. I figure if the socks let the very very slow leakage evaporate before it drips, that's good enough for me.

I had repeatedly patched pinhole leaks in the pressure tank until it seemed to be more patches than intact metal, and was afraid it would simply disintegrate one day.

So in 1996 I removed the original pressure tank and replaced it with the physically smaller (but equivalent) Well-X-Trol tank with an internal bladder (blue, in center).

The original tank was to the left, can still see the circle on the floor underneath the sock in the center picture. Came up with a mixture of galvanized pipe fittings to connect the new one.

The copper pipes from the inlet to the neutralizer periodically develop pinhole leaks; I put rubber gasket material and hose clamps on as a temporary fix until I can't stand no mo' --

and then depressurize and replace offending pipe section. The sock in center picture removed after such replacement in August 2010 when pic taken.

In 1993 my electric water heater started leaking and replaced it with a standard 55 gallon unit (A.O. Smith tank in right picture). All of the major work above done with K3VC's help (a real plumber).

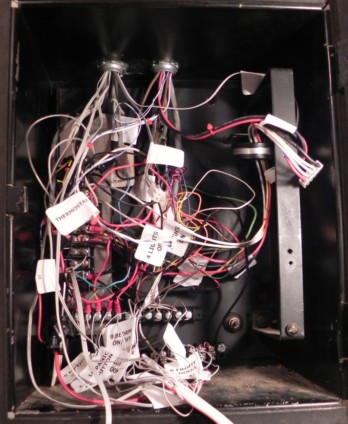

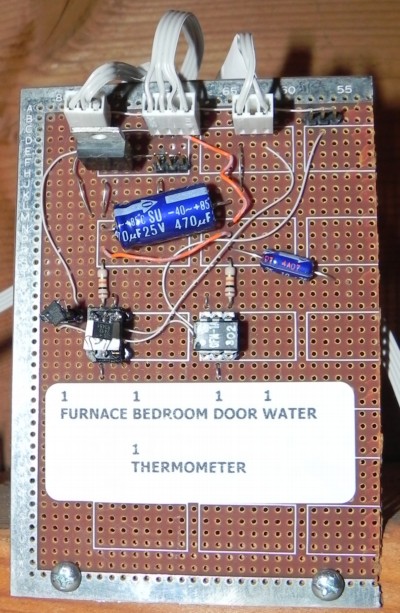

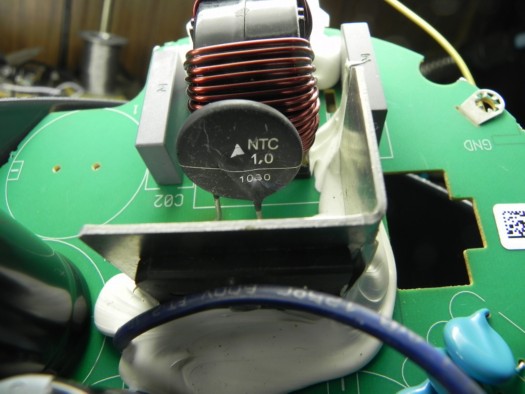

Automatic Well Pump Shutoff

I had a bad pipe leak and it ended up filling the basement with water before I noticed it and shut off the well pump. So, like closing the barn door after the horses had escaped, in September 2010 I installed an automatic well pump shutoff system. I bought a Basement Watchdog Water Alarm ($10 at Home Depot). It operates off of a 9 volt battery and has contacts on its bottom (which can be detached from the unit). When water on the floor is detected, it emits a high-pitched warning sound. I was very impressed: with no alert active, my DVM could measure no current drain! So it was less than 0.1 ua. It draws about 13 ma. when active. All in all, quite power conservative.

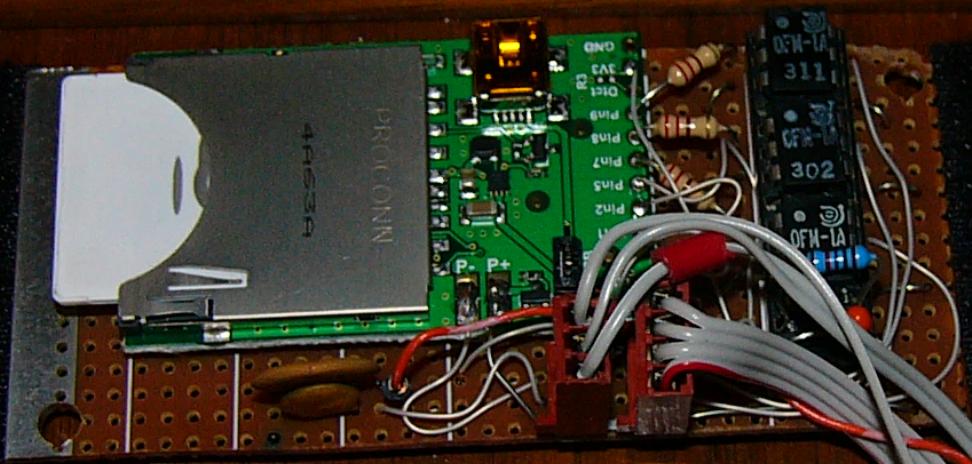

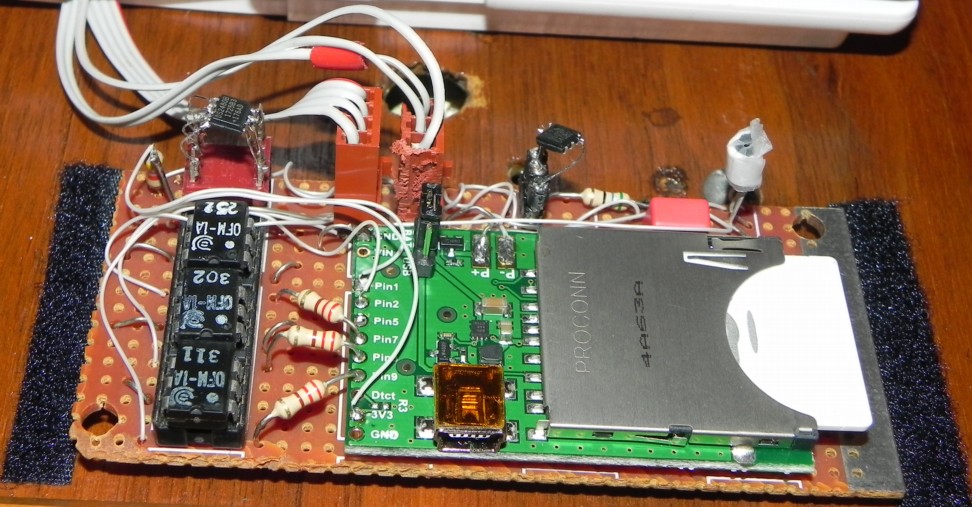

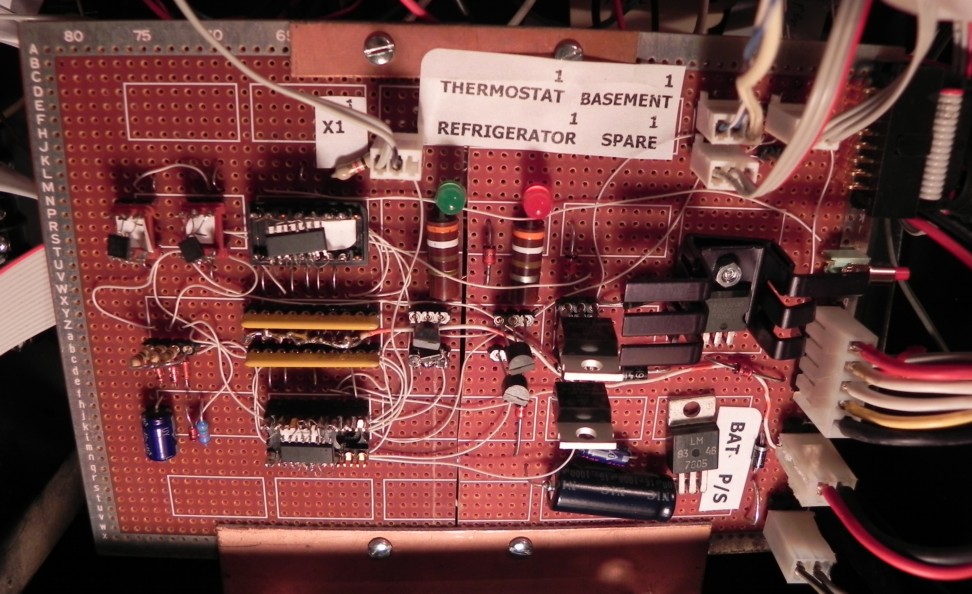

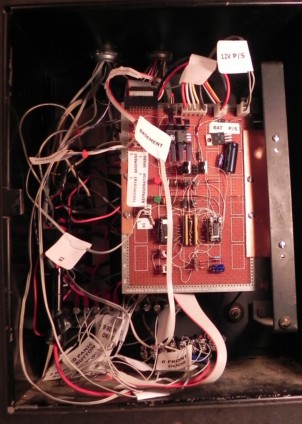

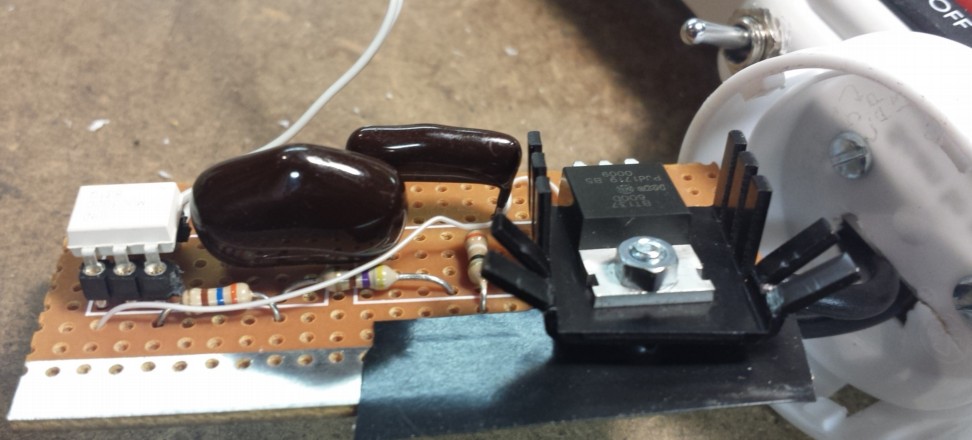

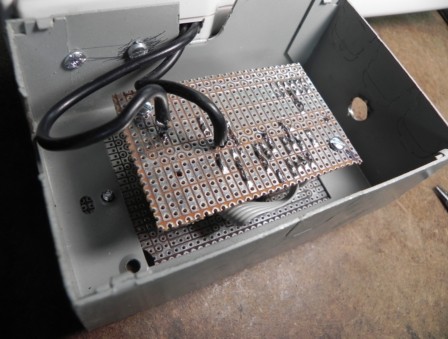

I designed a simple circuit with two optocouplers to detect the current drain when active and latch an output once tripped.

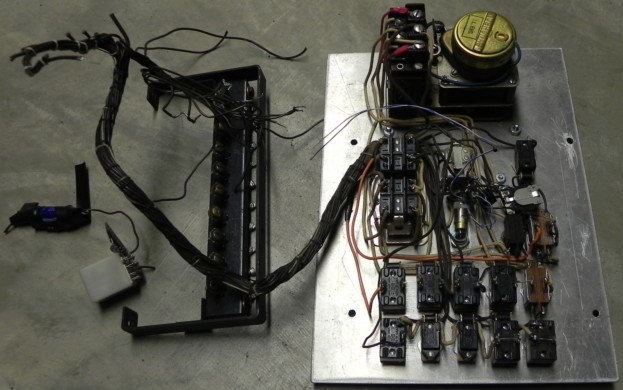

I wanted to be able to disable the well pump, which draws 9.6 amps @ 240 VAC, and was looking around for a relay which had hefty enough contacts in the normally-closed configuration.

I found a discarded air conditioner contactor, but it only had normally-open contacts and its coil was driven with 240 VAC itself.

I suppose I could have used it and powered the coil from the output of the pressure switch (which would only turn the contactor on while actively pumping), but I'd still have to drive a 240 VAC coil.

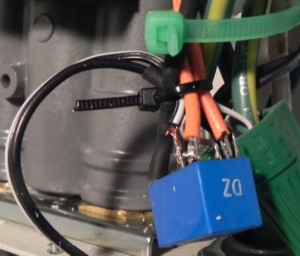

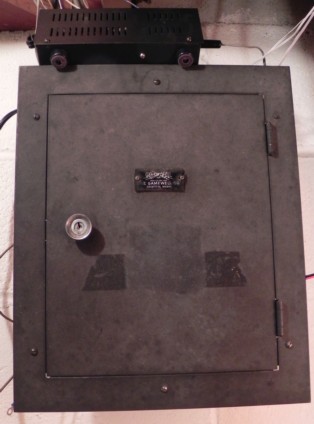

Then I found a discarded BGE (electric power company) radio unit designed to receive signals to temporarily disable an electric hot water heater during high demand periods.

It had exactly what I needed: a relay with normally-closed contacts with plenty of current/voltage handling capability, with a 12 VDC @ 100 ma. coil!

But instead of just taking out the relay, I saw that the box itself had a built-in 240 VAC in/12 VDC out power supply. Plus a convenient box to build it in! Just what the doctor ordered.

I just cut the 240 VAC feed going to the pressure switch (which in turn drives the well pump motor) and fed it through the new box.

The little protoboard on the right is my addition to the circuitry, it literally just contains two opto-couplers. I re-routed the relay coil to be driven by my circuit instead of the original receiver.

I powered the Watchdog Water Alarm from the 12 VDC ac supply, so no need to worry about batteries going bad.

Plus didn't even have to open the Water Alarm box, as the opto-coupler simply senses the power drain to the battery jack.

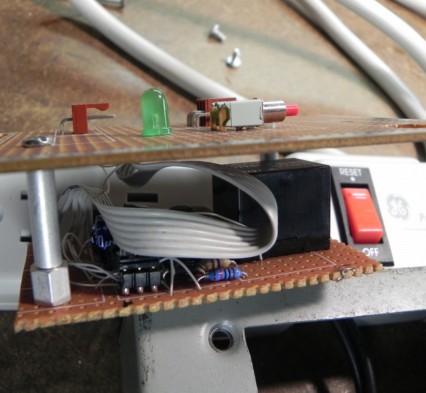

I added an LED (at the top, illuminated in the photo) to show that the relay has latched (and the power feed is inhibited).

To reset the circuit, I just need to temporarily remove power -- and there's already a switch on the wall that does that.

So the next time there's any type of leak in this inlet area (copper pipe pinholes most likely) at least it can't do too much damage -- plus I'll be alerted by the screech sound.

Here is the drawing.

I also put another Basement Watchdog by the basement door to alert me in case my outside pump gets clogged up. I used an AC adapter to power it instead of a battery.

In March 2009 the main (A.O. Smith) water heater from 1993 started leaking. Instead of replacing it with another similar unit, I did away completely with a tank-based system.

Installed the on-demand Eemax EX95 "Flow Controlled" Electric Tankless Water Heater instead (above left, also above the A.O. Smith tank picture).

It draws 40 amps @ 240 VAC (9600 watts!) -- but only while the hot water is actually being used. This has saved on my electric bill.

I know how to solder wires, but have never been too good at soldering copper pipe. Managed to cut out the original piping and put in the U-bends to the Eemax heater

with no leaks, pleasant surprise. That solved half the problem.

There is a long pipe run from the main water heater to the upstairs bathrooms, and it always took a good two minutes to get hot water there.

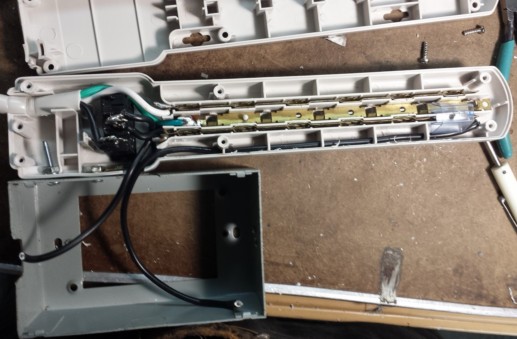

Originally there was a small electric tank heater in an alcove behind a bedroom closet (above right) which was fed from the main heater.

Only a few feet from the bathrooms, this gave a fast heat response. Too bad that heater had been broken for many years.

I would have replaced it eons ago, but all of the fittings were corroded, and access to the tiny spot through the closet made me fearful that I'd make

matters worse if I tried to remove it. But the EX95 in the basement doesn't have enough oomph by itself to satisfactorily power a bathtub fill or shower.

I took the opportunity to finally address the small water heater failure by replacing it with an Eemax EX65T tankless unit. This device is microprocessor controlled (PWM) to maintain a constant output temperature.

(The EX95 isn't, it heats the water as much as it can as it flows.) Necessary, because it is fed from the EX95 and the two together could possibly boil water.

It draws 27 amps @240 VAC (another 6500 watts!). I put a low-flow aerator on a bathroom sink which manages to provide just enough flow to activate the EX65T,

but is below the activation threshold of the EX95. Which accomplishes two things: (1) it saves power, because the main unit is not turned on (which would be useless anyway

because you finish handwashing before the hot water makes it upstairs to the sink); and (2) it keeps the flow rate low enough so that the EX65T by itself can heat the water sufficiently.

It's still necessary to wait a couple of minutes for both heaters to contribute to showers or tub fills to handle those rates. In all, this combination has proved satisfactory,

though not really quite as good as a tank heater. To be fair, the EX units are not rated for whole-house usage, but the stronger unit takes three 240 VAC 40 amp feeds,

which would have been more aggravation at the circuit panel. As it was, I was able to re-use the 240 VAC line to the main water heater

but had to run a new 240 VAC line to the EX65 (there was only 120 VAC in that location).

It was a challenge to do the pipe work in the alcove (above), especially as it's impossible to see all around the pipes that need soldering.

The hardest part was loosening the nonfunctioning existing valves in order to replace the washers. Successful on one (you can see the plumber's tape on the lower one),

I replaced the upper with a ball control type, and gave up on the bypass valve in the back which seems to be stuck closed which is what I need anyway.

I'd much rather work with electronics!

Reliability. The heating element in the main water heater opened in September 2010, 18 months after installation. The warranty is for one year. Concerned that this might be a recurring problem, I phoned tech support. Apparently they had made some unspecified changes in the design, and they sent me a free replacement element. Actually quite easy to repair the element anyway: the resistance wire (like a toaster's coiled spring) broke at the mounting screw. Just re-wrap on the screw. So I now have a replacement ready for next time. Repaired again 10/2014, and 6/2017; EX65T 2/2019. While it is easier to repair than with a traditional tank water heater which has to be drained first, it is a bit of a challenge to get the element out of the unit: twisting with a crescent wrench while pushing up with a screwdriver works.

Marey ECO150. On 8/21/2021 the heating coil on the downstairs EX95 opened again; no big deal, I now can repair it pretty quickly. Which I did by re-wrapping around the screw. But this time when I put it back together, the water flow sensor seemed to have failed. Turning the faucet on caused the unit's contactor (big relay) to chatter instead of clicking on (and off with faucet close). And it wasn't heating the water. This didn't portend well! So I took the heating coil element out again, and now it was decimated -- into many, many small pieces. At this point I didn't know how it actually worked, and thought that perhaps the small broken coil pieces were clogging a magnet that moves with the water. This coil was beyond repair, so I put in my only spare element. Now, after re-connecting, I posted a helper at the circuit breaker box; turned on the water, it chattered, and immediately had the breaker turned off. (The contactor didn't cease chattering with the water off.) My hypothesis was that the chattering contactor somehow destroyed the first heating coil, and I wanted to save the one good coil I had left! I can understand the coil opening if it didn't de-energize fast enough with the water flow stoppage; I still don't understand why it totally destroyed the coil, though. Anyhow, the circuit breaker action was in time to save this coil from burning out (which I checked with an ohmmeter instead of removing the element). Now I had to figure out how to address the water flow detection problem!

Marey ECO150. On 8/21/2021 the heating coil on the downstairs EX95 opened again; no big deal, I now can repair it pretty quickly. Which I did by re-wrapping around the screw. But this time when I put it back together, the water flow sensor seemed to have failed. Turning the faucet on caused the unit's contactor (big relay) to chatter instead of clicking on (and off with faucet close). And it wasn't heating the water. This didn't portend well! So I took the heating coil element out again, and now it was decimated -- into many, many small pieces. At this point I didn't know how it actually worked, and thought that perhaps the small broken coil pieces were clogging a magnet that moves with the water. This coil was beyond repair, so I put in my only spare element. Now, after re-connecting, I posted a helper at the circuit breaker box; turned on the water, it chattered, and immediately had the breaker turned off. (The contactor didn't cease chattering with the water off.) My hypothesis was that the chattering contactor somehow destroyed the first heating coil, and I wanted to save the one good coil I had left! I can understand the coil opening if it didn't de-energize fast enough with the water flow stoppage; I still don't understand why it totally destroyed the coil, though. Anyhow, the circuit breaker action was in time to save this coil from burning out (which I checked with an ohmmeter instead of removing the element). Now I had to figure out how to address the water flow detection problem!

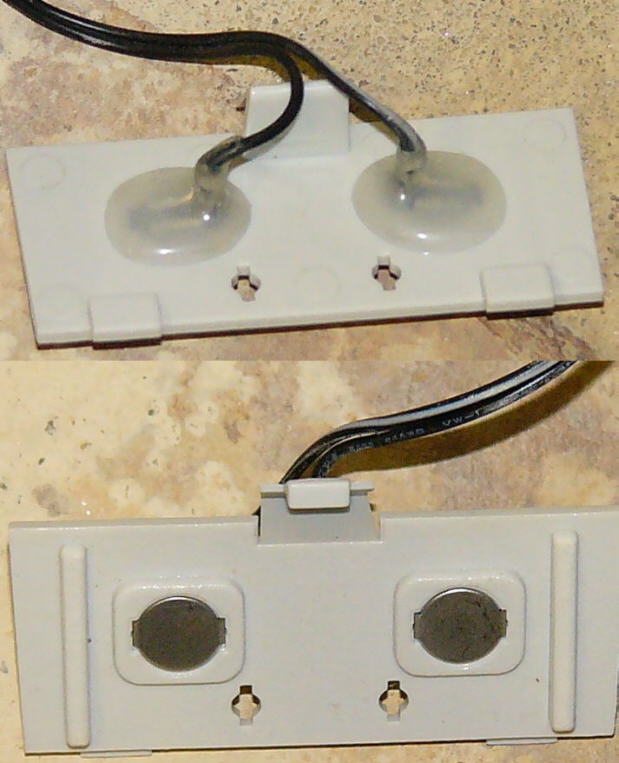

I thought that the two light reddish wires about a third of the way down at the picture on the right was the output of the water flow sensor; I removed it and found that it was in fact an overheat detector, to remove primary contactor power if the unit gets too hot. Not what I was looking for. The only other possibility was the black module labeled "UP." I found that this contained a conformally coated circuit board which was right against the heating tube. I figured that there is a magnet that rotates inside the chamber when water flows. There are two magnetic reed switches mounted on the circuit board which clearly pick up the motion signal from the magnet. Something had failed on the detector board. It contained a couple triacs, high voltage transistors (L601E3, Q601E3, 7G30W, 7J2UE) along with an MC14541BCP CMOS counter and other circuitry. I didn't see any shorts on the triacs or the transistors and I broke one of the transistors while removing it to be able to properly test it. Checked my junkbox and I didn't have any similar high voltage parts (240VAC) anyway. This was a Saturday and I didn't have hot water (but I really only use it for the kitchen sink and showers/baths, the upstairs heater is sufficent for the bathroom sinks). I really wanted to get it operational somehow. I did send a request to EEMax but of course no response.

To this day I don't really know what all the stuff on the circuit board does; but (with power off) I put an ohmmeter on the two reed switches as I opened and closed the faucet. I found that one seemed to reliably close with water flow and open quickly when turning the water off. The other one closed with water flow but stayed on when I turned the water off -- until I physically moved it farther away. So after giving up actually repairing the board, I decided to build my own simpler circuit. It's an exaggeration to call it a circuit! Even though the contactor coil didn't draw much current, I didn't have any sufficiently high voltage opto-isolators to drive it. I do have some known relays that are rated at 120VAC, but I figured no particular point in using one of those; I did have an unknown ratings relay with a 12VDC coil (blue at right), it's probably 120VAC also. I removed all of the wiring to the black module (the two black wires remaining simply drive an LED from the actual heating coil voltage and have nothing to do with the water flow sensing). My trivial circuit just put that one reed switch in series with the contactor coil and an external 12VDC power wart. I wired the two 240VAC wires through the normally-open relay contacts to the contactor coil. Since I had bypassed the fuse that was on the circuit board I was a little worried, so I put a 1A circuit board type fuse in series with the 240VAC as well. This is only the coil side of the contactor, the output is left alone and is powered directly from the feed. Without power to the heating coil, the contactor reliably clicked on with the faucet opening and off with the faucet closing; I felt satisfied enough so I restored the wiring and now I had hot water!

To this day I don't really know what all the stuff on the circuit board does; but (with power off) I put an ohmmeter on the two reed switches as I opened and closed the faucet. I found that one seemed to reliably close with water flow and open quickly when turning the water off. The other one closed with water flow but stayed on when I turned the water off -- until I physically moved it farther away. So after giving up actually repairing the board, I decided to build my own simpler circuit. It's an exaggeration to call it a circuit! Even though the contactor coil didn't draw much current, I didn't have any sufficiently high voltage opto-isolators to drive it. I do have some known relays that are rated at 120VAC, but I figured no particular point in using one of those; I did have an unknown ratings relay with a 12VDC coil (blue at right), it's probably 120VAC also. I removed all of the wiring to the black module (the two black wires remaining simply drive an LED from the actual heating coil voltage and have nothing to do with the water flow sensing). My trivial circuit just put that one reed switch in series with the contactor coil and an external 12VDC power wart. I wired the two 240VAC wires through the normally-open relay contacts to the contactor coil. Since I had bypassed the fuse that was on the circuit board I was a little worried, so I put a 1A circuit board type fuse in series with the 240VAC as well. This is only the coil side of the contactor, the output is left alone and is powered directly from the feed. Without power to the heating coil, the contactor reliably clicked on with the faucet opening and off with the faucet closing; I felt satisfied enough so I restored the wiring and now I had hot water!

This "fix" will probably work fine forever, but I remain a bit nervous about the missing detection circuitry. On the other hand, the worst that can happen is that the heating coil is energized with the water off and it will burn out the coil -- just as has already happened four times on this unit in 12 years. I eventually reached an EEMax tech on the phone (I'll skip the details on that). He said both the detector module and a replacement element are $56. Seems kind of expensive for the coil, though. The EX95 is discontinued but its replacement model uses the same element. So I started looking into other options.

I decided to switch out the EX95 with a Marey ECO150. While the system I had installed in 2009 worked, it had two deficiencies: the kitchen sink would get too hot to wash dishes at times; and one had to fiddle with the cold/hot mixture while leisurely taking a shower. The first problem is probably because I changed the kitchen faucet and I think it has lower flow than the original (which increases the temperature). The faucet is a single-lever type, and turning it a bit to the colder side lowered the hot water intake below the EX95's detection threshold; so the water would then become all cold and I'd have to repeat the cycle. The shower inconvenience is because I'm on a well, and the pressure tank cycles between 30-50psi. I had thought that because the EX95 drives the EX65T -- which is temperature controlled -- it would be okay. Now I believe that when the pressure is at 30psi and with a water-restricted showerhead, the EX95 was probably making the water too hot; the EX65T can't cool the water. This necessitated adding cold water, but when the pressure went up to 50psi the EX65T was regulating again and now there was too much cold. If originally I had gone with a temperature-regulated EX95T instead of the unregulated EX95, both problems might have been alleviated.

The ECO150 is regulated, and the temperature is set with a front panel control in degrees; the EX65T just has an internal potentiometer that has to be adjusted with trial-and-error. It also can consume up to 15KW as compared to the 9.5KW of its predecessor. It still uses a single 240VAC feed, but instead of a continuous 40A it can go up to a max of 60.8A. They recommend #6 wire, but I have #10 from the original tank water heater. I figure I'll see how it goes. I measured about an 8V drop with a full bathtub load; that's probably the only time it would be out of regulation, but I don't think it is even for that because the front panel temperature reading doesn't drop from its setting. And it is unlikely that I'd ever actually reach the max 60.8A draw as it'd be regulating in most instances. So I kept the 60A circuit breaker I already have instead of swapping it out for a 70A one which they indicate (circuit breakers notoriously need a lot more than the rated current to trip). Should I find it trips it's easy to put in a bigger breaker.

[10/5/2021 Update: Trying to remember my thinking when I installed the EX-95 -- EEMax suggests #8 wiring which is one step larger than the original #10; I had left it alone in 2009. But I checked that #10 Romex to the Marey unit after a bath fill and it wasn't warm -- it was hot! Not enough to burn down the house, but still... So I went to the bother of replacing it with the recommended #6. Which is quite unwieldy to manage. In the above picture you can see the old defunct wiring next to the new run.]

I was hoping to be able to mostly keep the plumbing (which would also mean it would be easy to swap the EX95 back in if the ECO150 failed); alas, the inlet/outlet are farther apart than on the EX95. The Marey unit is much larger than the EEMax, and the mounting configuration had the water connections farther out from the wall. Which meant that I would have to actually remove the pipes, cut them, and re-install instead of just swinging one of them outward a bit. Then I had a surprise problem: both units connect to 1/2 inch copper, but the EEMax has pressure fittings and the Marey fixed pipe threading. A trip to Home Depot found nothing; the floor helper actually sent me to Lowe's. Also found nothing in Lowe's. This was another Saturday, so the following week I went to a local plumber-supply store and found exactly what I needed for $6 total. I don't understand why Marey uses non-pressure fittings because with fixed pipes how does one disconnect? I'm not a plumber. So I did the dreaded pipe work. After three tries it didn't leak. I adjusted the temperature setting to 111 degrees (was trying for 110 but it jumps up and down several degrees at a time with the two buttons). The good news is that both of the identified problems are now gone! The idea is to set the hot water no hotter than is needed; then I only turn on hot at the faucets. The Marey unit seems to have a lower turn-on threshold than the EEMax, which in general is good. But now the discussion above about having the downstairs heater to not be triggered by the one low-flow bathroom faucet is out the window. Can't have everything!

My DVM has a temperature attachment, so I measured the water temp at the laundry room faucet right next to the heater, upstairs in the kitchen, and at the bathroom faucet. The Marey heater has a a somewhat under-damped feedback loop; you can see the temperature reading on the ECO150 go up and down as it adjusts. Sometimes it goes up to 118 or thereabouts, but it eventually stabilizes at the 111 setting. I found the same results at all three faucets with the DVM. I'm kind of surprised that there doesn't seem to be a temperature loss through the house. I guess the copper pipes just heat up to the water temp; I would expect there to be some loss from atmospheric conduction.

I did the switchout on September 8, 2021. I am hoping that the Marey unit will have better reliability than the EEMax; it seems to be heavier duty. I telephoned Marey and they do sell replacement pieces, but a casual inspection doesn't indicate what might fail. Figure I'll investigate that if/when the time comes. It has a 5-year warranty, but that doesn't particularly help when you want hot water NOW.

Basement Doorway Drain

My basement doorway has a drain, but where it goes, nobody knows. It does work after a fashion, but usually quite slowly. During heavy downpours the stairwell water level rises until it sometimes goes over the lip and leaks into the basement proper. I've bailed and mopped not that often, but more times than I'd prefer! In July 2009 I bought a central air conditioning condensate pump. I cut out a hole at the bottom on the box's side and covered with a filtering screen. Attached more ballast (35mm plastic film cannister) to its internal float to get it to trip at a lower water level than normal, and adjusted the microswitch activation hookup to change the hysteresis amount. Had to install a 120 VAC outlet outside the door, too. There's a plastic hose that takes the outflow away from the stairwell. So when the water level rises (but not to the lip's height) the pump activates and pumps the water away until it leaves a small residue. It works fine, but the biggest problem is that I have to clean it every once in a while or it gets clogged up with dirt prevalent in the woods.

Dishwasher

I had repaired my original 1967 model Tappen dishwasher over the years, but it was time for it to go. So in November 2010 I bought a new one. My biggest concern was that the kitchen floor was now a little higher than before because in 2008 I had had marble tile installed. I wasn't sure if I had the clearance to get the new one to slide into the space below the countertop before it would drop down off the edge of the marble. Inspecting the manufacturer spec sheets shed little light as they were incomplete. I just decided to go with hope and figured as a worst case I might have to remove a number of tiles to get it in and reglue them afterwards. Turned out there was sufficient clearance even with the new tiles. The biggest part of the job was rearranging the plumbing feeding the unit, as the connecting point was in the rear instead of in the front. Had to do soldering in the far back of the wall where I couldn't see behind the pipe. But it worked out!

...until August 2022! I found water coming from the laundry room ceiling (below the kitchen). Took me a bit to determine where the water was coming from -- the pipe connection to the dishwasher (which of course is hidden). Pulled the unit out from its spot. Left below is the original arrangement I had come up with in 2010, which now was dripping. The 1/2" copper is soldered to an elbow to fit a 3/8" threaded double nipple, which connected with a conversion fitting to match the flexible hose to the dishwasher itself (this fitting I think came from a dishwasher install kit). There is a washer in the larger section of this adapter, but it wasn't flat so I couldn't locate a replacement. I managed to get another equivalent fitting at Home Depot. But it still leaked. I was using teflon tape. Bought some pipe dope and tried that instead. No dice. Then I noticed that the threaded pipe itself was corroded and there was a small hole in it (so close to the end that it looked like the adapter/pipe connection was leaking). Got a replacement iron nipple pipe, was confident that would fix everything. I was wrong. Tried both the old and new adapter, but the washer just slid inside the threaded nipple section when tightened (must have been lucky in 2010, or maybe the original one had a flatter end to stop the washer from creeping in). No matter what I tried it still leaked, and I was becoming despondent. Back to Home Depot (fourth visit). Was going to get a brass version of the threaded pipe which had a larger end that I figured would secure the washer between it and the adapter (I believe that would have worked). But instead, I found a brass threaded coupling which had one end that matched the elbow and the other end that matched the flexible hose. So I could eliminate the adapter completely, always preferable -- less to leak (below right). Ta Dah! Works fine. I should check again in 12 years.

Kitchen Sink

My kitchen sink (above) was the original install from 1967. I scrubbed it, but it still didn't look that great. The faucet was corroding and beginning to leak. So in November 2013 I figured that I might as well replace the sink along with the faucet. The plumbing didn't have shutoff valves at that point, either. So I shut off the main supply, sawed off the hot/cold pipe feeds, and unbolted and pried the whole sink assembly out of the countertop. The new faucet uses a flex hose coupling, so all I had to do to update the plumbing arrangement was to unsolder the size reducer and attach new shutoff valves with a wrench. Much easier than replacing the dishwasher plumbing -- when I had to solder a new pipe configuration underneath the counter somewhat blindly. The original sink had a 6 inch depth and it was hard to tell how much clearance I had for the existing plumbing underneath because in addition to procuring the sink itself the drains have to be bought separately and mounted in the drain holes -- with differing heights. So I bought a new sink with a 7 inch depth. When I dropped it into the spot (after I had to enlarge the opening in the countertop a fraction of an inch with a saber saw) I saw I had an extra inch. So I returned that sink (it also had a minor ding on it that was undesirable) and bought an 8 inch depth version. The vertical height was then very close to the original, but amazingly the horizontal space between the two drain pipes was longer than the original! For the same size sink??? So I had to discard that drainpipe connector and put in a new one.

Here's the completed job:

I like the faucet and the sink looks great. But even though the actual double sink dimensions are identical to the original, this new one has more rounded corners. So pots that could lie flat before now do not. Oh, well!

Remodeling

In 1983 I put self-stick vinyl tile down on the unfinished basement clubroom cement floor.

Then I put up faux brick wall paneling in the clubroom to match the actual fireplace brick. Thankfully, the studs separating the clubroom area from the rest of the basement were already there.

Installed a bunch of fluorescent light fixtures on the ceiling.

At the end of summer 2008 home remodeling, replaced every single door knob, lock, switch/outlet cover, and doorstop in the house:

Washer/Dryer Wiring

The wall in the laundry room gets damp from moisture seeping through the cinderblock. The outlets for the washer and dryer were mounted directly on the wall and the dampness corroded the outlet boxes to the point that the 240VAC dryer wouldn't operate. In August 2017 I pulled the washer and dryer away from the wall and cleaned and painted it with Drylok Masonry Waterproofer to seal it off for a while (like I had the semi-finished clubroom done professionally in 2008). Then I wired up new 120VAC and 240VAC outlets for the washer and dryer -- but this time I mounted them on wood blocks to hopefully keep the moisture out of the wiring.

Lazy Boy

It felt funny sitting higher than I'd become accustomed to with the broken springs! Very pleased with the result. But it was a bigger job than I had anticipated.

Woodworking

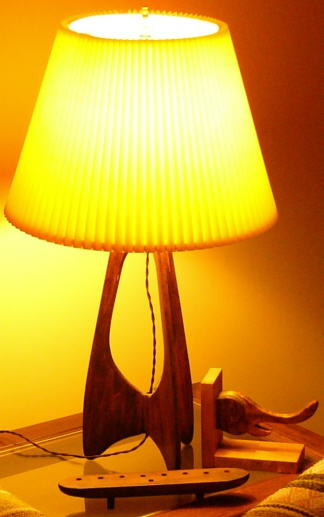

I believe it was in eighth grade shop class (1968) that I made these:

The lamp stand was a standard project(?), but I made the elephant and menorah for fun. Might have been ninth grade. Also made a necktie rack and a segmented dog in the seventh grade which I can't seem to find.

I know this doesn't belong here because they're not wood -- but I made these in ninth grade metal shop.

That's a combination hammer/screwdriver and a bottlecap opener.

I built this ham shack bench in 1969 and still use it. Very easy, since I covered it with contact paper instead of properly finishing the wood!

In 1983 I used my scroll saw to carve out this wooden road sign.

Painted it with fluorescent orange paint -- it was illuminated at night with a (regular) floodlight.

Even though I had layered it with protective spray lacquer, it needed regular repairs due to wood deterioration from its location in the damp woods.

Eventually it decomposed so much that I replaced it with a metal version.

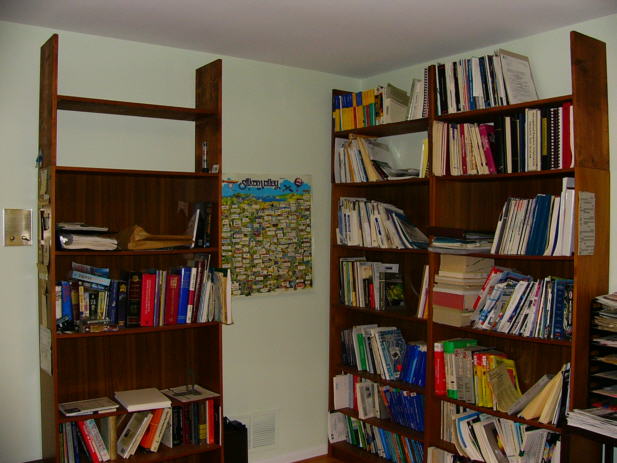

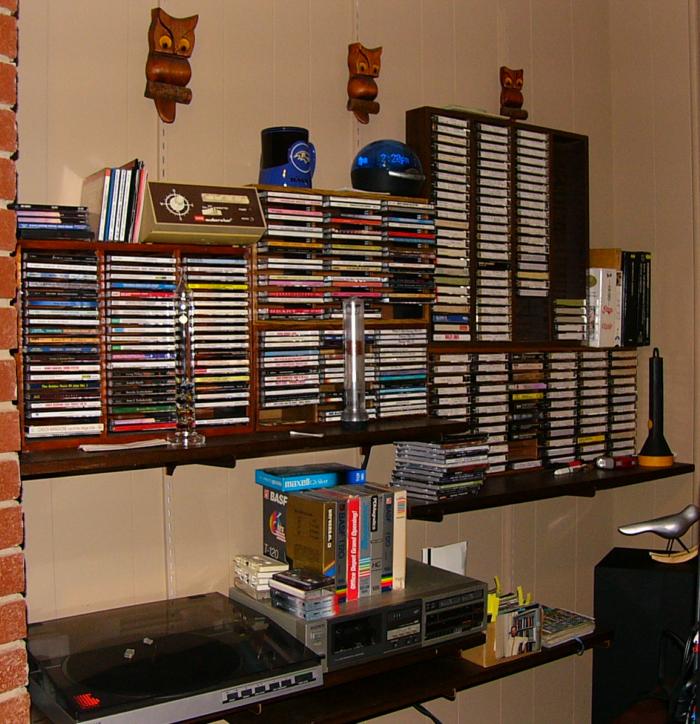

I had more books than would fit on my three purchased bookshelves, and the ceiling left more room...

so I built three "additions" for their tops to give me seven shelves each. At least I bothered to stain and lacquer them!

(In the 1985-1995 timeframe.) I had them all stuffed overfull; after the onerous task of boxing everything up to empty the room for remodeling (2008), I never fully unpacked and replaced all of the books... yet.

I bought the TV in March 2004 and constructed a custom console for it. It needed to swivel, so I put six wheels underneath (hidden by the moulding strip) in a fixed circle orientation.

There's also a center bolt-mounted pedestal slightly higher than the wheels to facilitate the rotation. After cutting, assembling, and staining I believe I used up the entire can of Minwax!

In August 2014 the CRT HDTV was 10 years old and I figured it was time to invest in a flat panel for its replacement. I had procrastinated mostly because I didn't want to deal with re-doing the wood console.

So I built a two-shelf interior (a Telcro II cabinet smoked plexiglas front cut in two with wooden dowels as legs) to hold the stereo and video equipment, and placed the TV on top.

Bird Feeders

(Also see my About Birdcam page)

Main Feeder: I went through a variety of feeders on the dogwood tree at the front of the house.

I started with a simple purchased one that looks like a birdhouse (in the center post feeder shot, below). The squirrels happily sat on it and finished its contents off.

I then tried a commercial "squirrel proof" one that just gave them a convenient cage to hold onto.

I tried blocking the treetrunk with surrounding sheet metal to prevent the squirrels from climbing up to the feeders. Had to keep expanding it until it actually worked, but it looked extremely unsightly.

Additionally, some brave squirrels climbed up adjacent trees out to overhanging limbs and attempted to drop down to the feeder. They sometimes made it and sometimes missed --

plummeting maybe 60 feet or so to the ground -- dazed, yet unfazed. I really didn't feel comfortable encouraging animal suicide, though. I abandoned the blocking tactic.

Then I started fashioning my own feeder construction attempts:

In March 2002 I built one (above, but less the top container and tubes) from the top of a cake server (upside down). I put a plastic container inside to keep the seeds at the periphery near the access holes.

Below the separation by another plastic container, there's a shelf made from a suspended ceiling light panel.

At first I had the feeder directly suspended by two chains (the seed cavity top is a plastic disc sold for isolating squirrels), but the squirrels just walked down the chain,

hooked a foot on the chain -- and leisurely served themselves by reaching to the feed holes. I added another plastic container to the top and covered the chains with clear cylinders (first and second photos above).

As seen in the second images above, they still managed the same feat. I put a taller container at the top (third shot, where I also changed the bottom container).

The squirrels still could jump to the tray, which was flimsy enough not to support their weight -- but I was afraid the panel would break. In fact, it did:

You can see this arrangement just gave the squirrels a convenient sitting place to eat. But I was almost there, the salad bowl needed to be attached to the seed cavity and free from the tray. I determined that the feeder requirements were: (1) there must be nothing for squirrels to grab or hold on to; (2) the top must be large enough to fully prevent them from reaching down; and (3) it should hold more seed to make it last longer between refills, because taking it down was cumbersome. So in September 2002 I designed an entirely new one out of plexiglas (acrylic plastic) from scratch:

The inverted pyramid container directs all of the seed to the bottom feed holes; is large enough to hold 25 pounds of birdseed (which lasts 4-8 weeks); and provides nothing to grasp. The tray is plexiglas, much stronger than the ceiling panel. I added clear moulding edges (with spring releases to flip down when squirrels jump to it) to trap fallen seed. The pulley/weight system is retained, but the separator (salad bowl) is attached to the top section and not the tray itself -- when the tray drops down, there's nothing to grab. Originally (above left) the roof was the same size as the bottom tray, but I modified it to provide an overhang on all sides to make it impossible to drop down onto the tray (two right photos). Initially the weight was a plastic container filled with counterbalancing rocks, but it was unsightly. The final configuration is at the right, filled with aquarium rocks and fake seaweed. I also suspended it with a double rope through pulleys on the tree branch, so I can hoist it up and down for refilling. The squirrels occasionally jump onto the tray, but they immediately fall off. Success! It has remained unchanged since the beginning of 2003, except I redid the roof with quarter-inch thickness material -- as it had to be strong enough to withstand the weight of a foot or more of snow.

Post Feeder: I also put some birdseed on a tray I quickly attached to the entrance post lamp.

At first I just attached it to the side of the post with wire, and of course the squirrels just walked right up the post and sat on the tray.

So I added some sheet metal to the sides and surrounding the post to prevent them from climbing up or grabbing on when jumping from the ground, etc. (left, 8/2003 shot):

That was kind of ugly, so after my plexiglas experience with the main feeder, in 2004 I constructed a new post feeder that surrounded the post (center shot).

The squirrels couldn't simply climb over it, but still some enterprising ones managed to catapult themselves off the post and around to grab onto the short side.

I added some flat horizontal extensions on those sides with limited success. Then I came to the final solution: the long vertical extensions (right).

Now no more squirrels on the post feeder -- except when we get a few feet of snow, which puts the shelf within jumping distance from the new ground level.

Miscellaneous Electronics

You needed a special sense of humor to appreciate this in the 1960's/1970's:

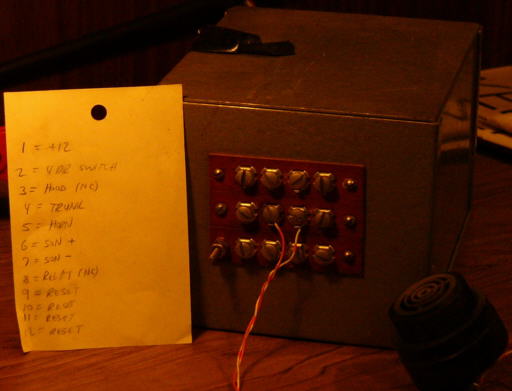

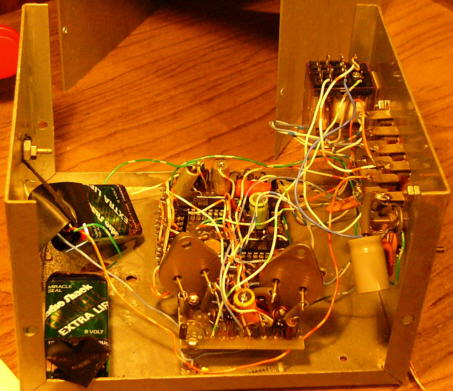

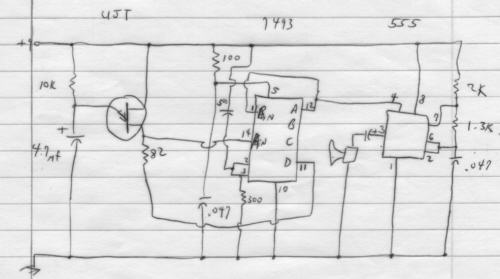

I built the timeout box at left circa 1970.

I think this is the schematic.

You power a radio from it, set the on period, and go to sleep. It'll shut down as desired. Nowadays all clockradios do this.

The Transistor/Diode Analyzer at right is from the 1970's. Connect an oscilloscope to it and it generates voltage/current curves.

I bought lots of (unknown) "surplus" semiconductors from sources such as Poly Paks for pennies and measured the parameters to see what I had.

It's Academic

We were buying key systems from T.I.E. in Connecticut -- the KSU's (main phone box) had to be put together with wirewrap dependent upon the installation's requirements, but the circuit boards were ready-to-go. Initially my job was to build and then design simple modifications to the standard T.I.E. gear. This included an interface to permit callers on hold to hear a radio station or a tape deck instead of the built-in mechanical chime; ring a bell (a really loud bell, enough to wake up the dead) for warehouse operation when the phone rang; conference units, etc. Later I tried my hand at designing speakerphone circuitry, with a modicum of success, but not really good enough for commercial usage. Here are my various schematics.

The brothers who owned the company seemed to have some trouble differentiating real business matters

As a second-year EE student, I was very happy to be designing circuits with operational amplifiers (which I had just learned about from Prof. Westgate's class) and I probably wasted unnecessary time with all that.

But they didn't care (as if they even knew), because they were paying me so little (but still a few pennies more than I had been getting sweeping floors!).

I had digested in detail every single T.I.E. schematic until I understood precisely how the phone systems worked.

Which really wasn't required to build, install, or maintain them.

The owners (two brothers from New York) supposedly acknowledged my capability by making me

The owners (two brothers from New York) supposedly acknowledged my capability by making me

I remember one particularly humorous maintenance call: #2 brother had gone to one of our customers and tried to get him to pay his bill. He wasn't having much luck, so he went over to the KSU and started randomly pulling out circuit boards. Of course, the phones started going dead all around the office. Needless to say, the tactic worked and the customer immediately wrote out a check and begged to get his phone system back up. The #2 brother might have been a good salesman, but he had no technical knowledge whatsoever. And he began plugging cards back in without considering that in fact they are supposed to go into particular slots. So he burned out the whole thing. That was a service call I took, quite happy to simultaneously be correcting a boss' ineptitude while getting the higher salary!

Later on, as the company failed (the brothers treated it more as a personal playground rather than a serious business) and the workers gradually departed (which tends to happen when paychecks bounce), I ended up doing all of the company's maintenance -- and they did in fact pay me the higher rate all of the time. As the very last employee (I myself had to resort to some trickery to get my final pay from brother #2), I carried a beeper with me to class (in silent mode) and checked in on service calls in between lectures. This was before beepers became commonplace devices for drug dealers and tethered children (long predating cellphones). When that experience was over, I vowed never again. And I never did.

In a strange Twilight Zone type of quirk, years later when I ended up at Telesaver, they moved into the exact same office space that Sonaphone had a dozen years earlier inhabited: 20 Gwynns Mill Ct.

There was no connection whatsoever between the two businesses (other than me, and I had nothing at all to do with location selection).

I had a bunch of the leftover Sonaphone stick-on aluminum labels which I made various uses of, including small heatsinks. I thought it was funny that there were two misprintings on them:

the city name, plus we were the only U.S. company with an 11-digit phone number!

I built two versions of this automobile alarm system:

The

first was TTL (probably in 1974, the schematic is undated) -- it drew more quiescent power than one would like for a continuous drain on the car battery, and was somewhat susceptible to transients causing false alarms.

The second version was CMOS (February 1975),

which solved those problems. They both functioned identically. The alarm monitored the dome lamp; once a door (or hood or trunk switch) was activated,

the user had to close and re-open the door within five seconds to disable it. There was an under-dash enable/disable toggle switch. My system required no special keys and it wasn't

necessary to go to one particular spot on the car to disarm, as was customary at the time. When the alarm tripped, it honked the horn (on/off), enabled a Sonalert beeper (in

case the thief unplugged the horn), and disabled the starter circuit (in case the robber wasn't worried about drawing attention). I knew better than to interrupt the ignition circuit (:>).

After a false alarm burned out my car horn, I added a two minute timeout on the horn activation. One 9V battery was in case the thief cut the battery lead, it would still activate

the Sonalert; the second 9V battery boosted the voltage to the Sonalert to make it louder. The alarm was on my 1972 Chevy Nova and then my 1981 Toyota Tercel. I retired it when I

bought a 1995 Infiniti, which has a built-in alarm. In service 20 years, not bad!

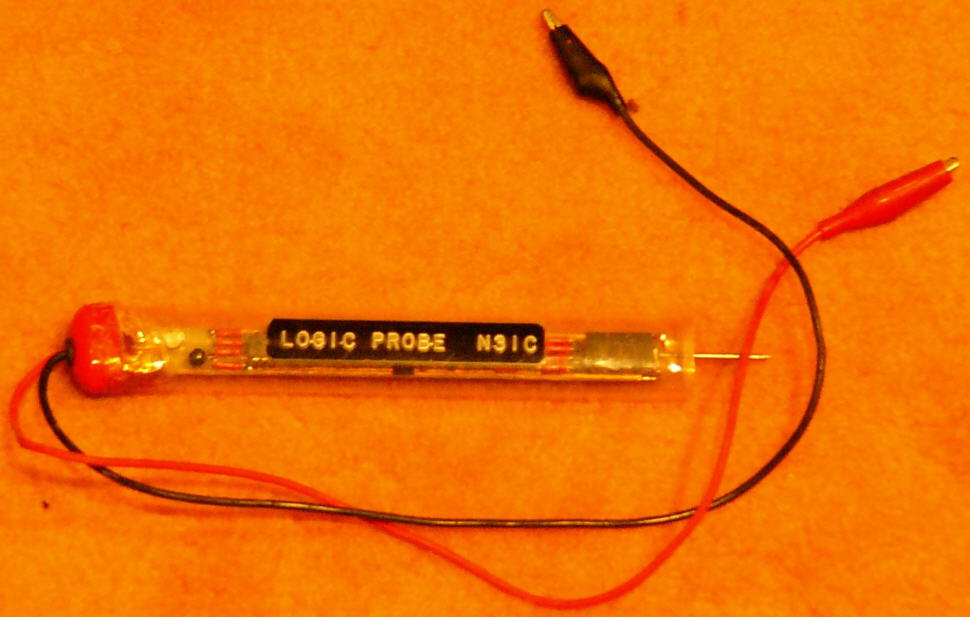

Every digital dabbler must have a Logic Probe:

This circuit was in September 1975 Popular Electronics. The only tricky part was making it small enough to fit into a toothbrush tube.

The 7-segment display shows H (high), L (low), P (pulse), or O (open circuit). This is no big deal now, they all do that.

But back in the 1970's most probes just showed High or Low. Had to etch a small circuit board from the magazine artwork.

Here's the article.

You can never build too many power supplies:

Beat the Reaper

At the JHU Amateur Radio Club, those rigs cost a lot of money. So we earned extra cash at the annual Spring Fair.

All of those fairs run together in my memory, but these pics are probably from the 1974-1976 time period.

We had a prime spot at the top of the stairs between the Gilman and lower quads (center pic looking south towards Shriver Hall).

Steve Fick WA3EVY (now N3TE) came up with his "Beat the Reaper" game of skill. We built this very complicated (haha) electronic challenge for fairgoers.

Can't find the schematic.

You had to navigate the metal loop from one post to the other without touching the bent copper tubing.

One false touch and a "lose" gruff buzz latched and ended your attempt.

If you make it all the way across and touch the end braid, you "win" and latch a nice pitched tone sound.

Of course, we held the power on/off button in our

Steve writes: I remember a very raspy buzzer, with a 12" diameter 35mm film can as sounding board, which was triggered on timeout or when the wand hit the wire.

The control circuit was built around a thyratron (2D21) controller from my junk box.

I remember a length of RG-8 shield, at the end of the wire and insulated from it, which the customer touched to trigger a success indicator. However, I don't remember what that indicator was.

It might have been a Mallory Sonalert (I agree). I can't find the schematic either.

I remember visiting the shack in 1985, shortly before it was leveled to make way for the sculpture garden.

The Reaper tubing and poles were still there. The club was inactive, and the place was in tatters. All the gear within about 2 feet of the floor was ruined, though, by a flood.

Marc Leavey WA3AJR was a real (original) Trekkie, and he wanted a Communicator.

I designed a circuit for him which mimicked the sound the TV show's devices made when flipped open.

At the right is the initial version of that circuit. He constructed a pretty good imitation of the icon and built in the circuit. Cool (well, back then it was! Remember, this was before cellphones.).

He

published an article on it in the February 1976 issue of 73 Magazine. It was made into the lead magazine article and garnered the cover (at left)!

Marc Leavey WA3AJR was a real (original) Trekkie, and he wanted a Communicator.

I designed a circuit for him which mimicked the sound the TV show's devices made when flipped open.

At the right is the initial version of that circuit. He constructed a pretty good imitation of the icon and built in the circuit. Cool (well, back then it was! Remember, this was before cellphones.).

He

published an article on it in the February 1976 issue of 73 Magazine. It was made into the lead magazine article and garnered the cover (at left)!

In October 1974 while an undergraduate I did a consulting job for Barry Hirschowitz to design and construct some type of medical device.

I can't remember exactly what it was for, but think that it measured small skin voltages.

I might have been given schematics of a commercial device based on vacuum tubes that performed a similar function.

It was essentially a very high input impedance voltmeter, and drove a large analog meter

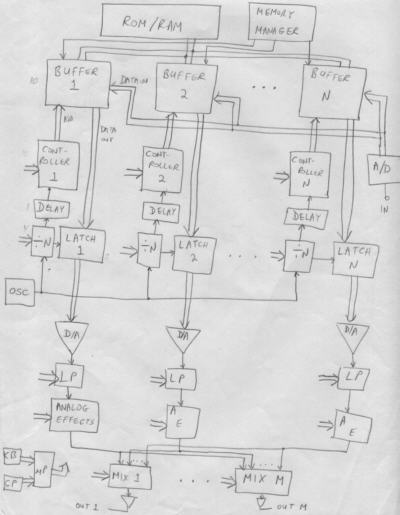

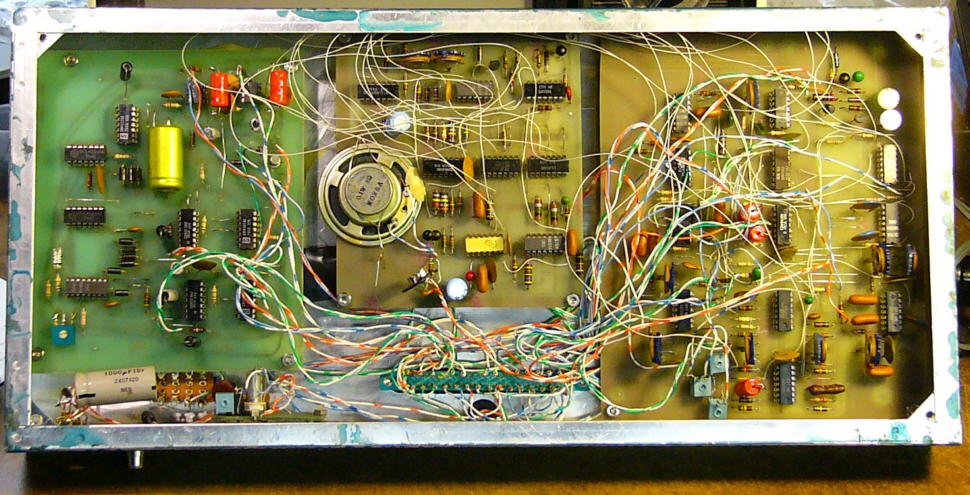

Replicating Digital Synthesizer

In 1975 fellow undergraduate student Eugene Mauro came to me with a proposal.

Music synthesizers of the day were analog devices which created interesting but clearly artificial sounds.

His idea was to use nascent computer technology to record and play back real musical instruments at different rates to produce a new kind of music synthesizer.

He was a musician, and had taken some electrical engineering courses, but knew that he couldn't design it himself.

Eugene's plan was to write up design details, build a prototype device, and obtain a patent for it.

He paid me some money (I wouldn't do the work purely on speculation), and we were to share in the profits when they came rolling in.

He had a patent attorney working with my writings, but the predictable happened: he ran out of money getting the legal work done.

Let alone to have enough to actually build the prototype, which we estimated would cost thousands of dollars.

The design was fairly large, consisting of multiple microprocessors (interesting that I selected the COSMAC processor for it) --

but I had (and still have) no doubt that we could have built it and that it would have worked.

He had little choice but to abandon the project.

In 1975 fellow undergraduate student Eugene Mauro came to me with a proposal.

Music synthesizers of the day were analog devices which created interesting but clearly artificial sounds.

His idea was to use nascent computer technology to record and play back real musical instruments at different rates to produce a new kind of music synthesizer.

He was a musician, and had taken some electrical engineering courses, but knew that he couldn't design it himself.

Eugene's plan was to write up design details, build a prototype device, and obtain a patent for it.

He paid me some money (I wouldn't do the work purely on speculation), and we were to share in the profits when they came rolling in.

He had a patent attorney working with my writings, but the predictable happened: he ran out of money getting the legal work done.

Let alone to have enough to actually build the prototype, which we estimated would cost thousands of dollars.

The design was fairly large, consisting of multiple microprocessors (interesting that I selected the COSMAC processor for it) --

but I had (and still have) no doubt that we could have built it and that it would have worked.

He had little choice but to abandon the project.

To this day, when I pass by the dozens of inexpensive Casio synthesizers in the electronics stores -- which are simply cheaper modern-day implementations of his Replicating Digital Synthesizer -- I cannot help but think of Eugene and lament that he never got any credit, let alone millions of dollars, for this. He had a music store in Waverly for a while. I ran into him maybe ten years later there where he had happily recently obtained some professional recording studio equipment.

Here are my description and design documents.

MET-1

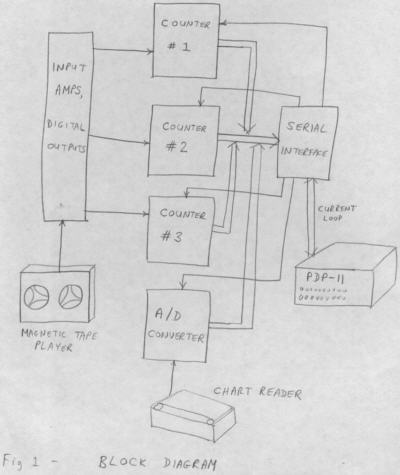

I designed an interface system for Maryland Electrical Testing (MET) which was delivered in September 1977. They were conducting an extensive powerline measurement study, I believe for the Army in Virginia. They had purchased many magnetic tape recorder units produced specifically to log AC voltage, current, and phase for that purpose: these recorders moved very slowly -- I think each tape cartridge lasted around a month. The recorder manufacturer also sold a reader device which would play the tapes back (at high speed) which connected in some way to a computer system for analysis. Which is exactly what MET needed. But it was extremely expensive. They thought "what's the difference between a tape recorder and a tape player?" The electronics! They figured they could modify one of the inexpensive recording units to instead play back the tapes. And they contracted this then grad student to design and build them the electronics for it (ostensibly for a lot less money than the commercially available reader).

This was an interesting project. The tape recorder had a capstan to keep the record speed fixed at a slow rate; on their modified unit they had removed the capstan.

This let the tape cartridge spin as fast as the drive motor could spin -- which was quite fast, and moreover, not at a fixed speed as the tape wound from one side of the cartridge to the other.

The record electronics was of course bypassed and my circuitry hooked directly to the tape track head coils.

This was an interesting project. The tape recorder had a capstan to keep the record speed fixed at a slow rate; on their modified unit they had removed the capstan.

This let the tape cartridge spin as fast as the drive motor could spin -- which was quite fast, and moreover, not at a fixed speed as the tape wound from one side of the cartridge to the other.

The record electronics was of course bypassed and my circuitry hooked directly to the tape track head coils.

I didn't really know what the signal level coming off of the head would be, but a measurement showed that it was in the microvolt range. Seemed kind of low (maybe in retrospect), but I designed the analog front end to amplify it a gazillion, used differential mode, and employed shielded wiring because that much amplification was sure to run into noise and pickup problems. It worked, but not as well as we'd prefer -- there were read errors after signal discrimination (NRZ decoding). One of their guys scratched his head and thought "Shouldn't the signal level be higher than we're seeing?" He looked a little more closely at the unit, and guess what he found? There was a permanent magnet hidden in front of the tape head to erase the tape! Made perfect sense, this box was sold as a recording device! But we were using it to play back the tapes, and every time we ran a cartridge through it, the tape was being erased more deeply (that might have been the big clue). I had so much signal gain in my circuitry that it was (partially successfully) reading the residual signal left behind after erasure. (Why couldn't the NSA use this same technique to read the erased 18.5 minutes of Nixon's Watergate tapes?) He removed the magnet and the signals were now in the millivolt range. I trivially reduced the gain in my front end, and presto, the tapes decoded perfectly reliably.

This project was a little after my MAXI micro endeavor, and I used some of the same techniques: 44-pin edge connector Radio Shack prototype wiring boards and card cage. I even used an Intel 8224 clock generator chip to drive the UART -- I knew it was overkill, and the 8224 ran notoriously hot -- but it certainly could do the task without a care on my part, and as a bonus it included the power-on reset circuit I also needed. This was not a microprocessor-based project, it was pure hardware. It had to pick up the signal and clock data off of the tape head, decode the NRZ pulses, and transfer the information to MET's PDP-11 minicomputer. I used a standard current loop serial interface to the PDP-11, but knew that the computer and interface would not be fast enough to collect individual pulse info. So I designed in hardware counters which the computer could poll periodically to retrieve the information. My undergraduate PDP-11 experience came in handy for this project even though I didn't really have to directly deal with that end of the system. After the magnet episode, it worked great without any problems. Almost as an afterthought, they wanted to be able to use the same device to input paper chart power data as well. They had constructed a tablet type of gizmo that let them put a printed chart on it and have a clerk meticulously move a stylus to various points on the graph; it was attached to a potentiometer. So my box had a mode to read the pot voltage with an analog-to-digital converter (ADC) and transfer the data to the PDP-11 whenever the operator pushed a sample button. Sounds crude, but this was 1977 and it did everything MET wanted.

Sometimes when you don't hear back from a customer after a while you wonder if equipment is even being used.

But I ran into them a number of years later, and learned that they used my MET-1 interface for quite some time. Nice to know!

Before specialized digital chips came out, it took a lot of circuitry to create the Pong video game:

I combined two separate games -- Pong and Spacewar -- into one box. The edge card connector was double-sided; you plugged the cable in one way or the other to select which game.

These CMOS circuits were in the magazines. I added a channel 3 modulator so you didn't need a video input (which wasn't common in the 1970's) on the TV.

I was very impressed with these games, you could even play the machine! Until shortly thereafter when single-chip solutions came out, which put these games to shame (:<).

Frequency Counter/Digital Voltmeter from around 1976?

Every mad scientist's lair must have a Jacob's Ladder:

I bought the circuit intact from one of the hobbyist parts suppliers in the 1980's, it's just a transistorized flyback high voltage circuit.

Powered from 12 VDC.

I have a looseleaf binder filled with many other schematics I had designed. I just don't have the circuitry anymore, or can't quite remember what it was exactly for.

Maybe that's why I take it out on my students now, forcing them to write better documentation!

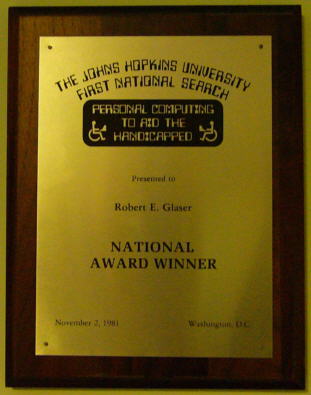

In 1981 the first DTMF decoder IC's had come out, so I designed this Message Converter as an entry in a contest:

It used an 8748 microcontroller (actually an 8035/2716 combination, which was much cheaper at the time) and the DTMF chip to listen to tones on the phone line and convert them into ASCII, Baudot (typical TDD terminal then), or Morse code (LED illumination) formats.

(To permit the deaf to use the phone.) Each letter used two depressions, the first the button with the desired letter, followed by 1, 2 or 3 to designate which letter.

For example, 23 supplies "C" because the "2" button has "ABC" on it.

That's my MAXI micro Term, TV monitor, and two telephones to demonstrate the system at the show exhibition in DC.

When my wooden road sign deteriorated amidst occasional repair, I replaced it with a more modern version in October 2003:

It has 198 line powered LED's (draws 14 continuous watts). The colors don't show up too well in the photos -- the name is green, number yellow, and arrow red.

It is visible even in daylight, and deliverymen appreciate it!

Built onto two aluminum rack panels (front/back).

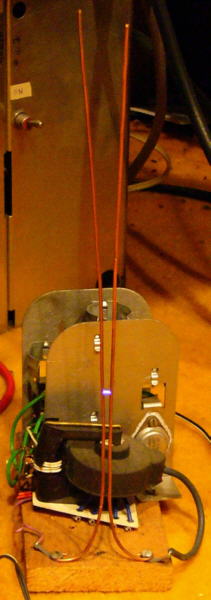

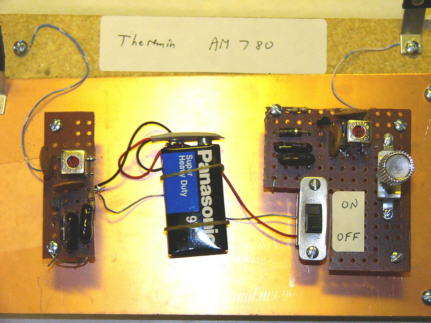

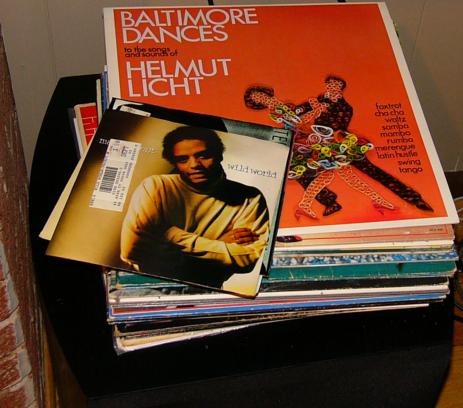

I built a Theremin for my friend Larry Kruger as a birthday present in February 2005:

The old-fashioned device has two RF oscillators, one fixed and the other nearly zero-beat to the first with the frequency trimmed by nearby body capacitance.

You wave your hands around it and the frequency difference comes out as a variable audio tone on an AM radio (my beer can radio above).

Very popular device to generate eerie sounds for old science fiction movies!

Wire Recorder

In February 2012, my friend Russ N3YI brought over a wire recorder that had been in his family since before he was born. Apparently these were predominant in the late 1940's and early 1950's; after that reel-to-reel tape recorders took over. His unit was a Webster-Chicago model 180. Here is some literature on it that was with the box. (I am amused at the drawing on page 4 of the lady in heels easily carrying the "portable" 27-pound unit. Compare that to a two pound MacBook Air!)

The unit had been passed down to him, and since he was a kid he had wondered what the recordings that were on the spools of wire sounded like.

He had already had the AC power cord repaired, but nothing happened when it was turned on. I found the power fuse and it looked like it had disintegrated; so we replaced it and turned the power on.

The tube filaments lit up -- after about 20-30 seconds, one of the plates was glowing red. Then the new fuse blew. I knew that the most likely failure mode for this type of gear not turned on in probably 50 or 60 years was the electrolytic filter capacitor.

So I actually had slowly ramped the line voltage up with a variac rather than directly powering from 120VAC. I'm guessing that replacing that cap will restore the box to operational order, but didn't bother with that.

Our goal was simply to retrieve the audio recordings for Russ (at right).

The unit had been passed down to him, and since he was a kid he had wondered what the recordings that were on the spools of wire sounded like.

He had already had the AC power cord repaired, but nothing happened when it was turned on. I found the power fuse and it looked like it had disintegrated; so we replaced it and turned the power on.

The tube filaments lit up -- after about 20-30 seconds, one of the plates was glowing red. Then the new fuse blew. I knew that the most likely failure mode for this type of gear not turned on in probably 50 or 60 years was the electrolytic filter capacitor.

So I actually had slowly ramped the line voltage up with a variac rather than directly powering from 120VAC. I'm guessing that replacing that cap will restore the box to operational order, but didn't bother with that.

Our goal was simply to retrieve the audio recordings for Russ (at right).

I pulled all of the tubes to prevent the (again replaced) fuse from blowing. The good news was that the motor (there is only one) worked. After some cleaning with alcohol and judicious lubrication I could make it go forward to play and reverse to rewind. It still took some finger action on the mechanism to get it going in either direction. The rubber mountings had deteriorated and in some cases turned to dust. The wire broke a few times in the process of getting the mechanism to do its job. It's kind of interesting that there is a mechanical part which moves the head up and down as the wire winds onto either the supply or takeup spool. This evenly spreads the wire onto the spool much like a sewing machine, and prevents bunching. I also thought it interesting that there is no capstan -- which on reel-to-reel and cassette decks keeps the tape velocity constant as the diameter of the takeup reel increases throughout the play time. This design simply used a large diameter takeup spool, so even when it is filled from the supply spool its diameter isn't much greater than at the start. The motor speed and idle wheel reductions set the transport speed.

With the tubes removed, we had no active electronics. But we didn't need no stinkin' tubes! I attached the leads from the head to the input of a (transistorized) audio amplifier (in between the two laptops in the picture below). We threaded the wire through the (playback in this mode) head and the takeup reel and got the wire moving. We could hear the audio from the past emanating from the amp's speaker! The rest would be a cakewalk.

I tried feeding the head signal directly to the microphone input on the laptop, but there wasn't sufficient gain. So I connected the head to the input of the transistor amplifier and the amp's output speaker jack to the laptop's line-in jack. With Audacity I could record the session and edit it afterwards. There were sections of the wire ("tape") that had great audio levels and others that were much lower. Some were simply people talking too far away from the microphone, but on other sections I think that someone pushed the record button over top of the previous recording and mostly erased the former data. I selectively edited portions and amplified them (a lot) to try to bring the sound up to a listenable level. Of course that boosts the noise level quite high. Another problem is that I live too close to WCAO-AM (they moved their transmission towers to the neighborhood after I moved in!). So in the sections of the recordings where I amplified it a lot there is a residual background of the local radio station. Oh, well.

In the end, I made up audio CD's and MP3's for Russ of five recordings: Sondra's sweet 16 birthday party (his Mom); Rosie's birthday party from February 29, 1952 (Russ' great-grandmother whom he is named for); the Kaufmans' 25th anniversary party (Russ' grandparents); a recording off of Philadelphia's WPGM fm radio station (I think those are the call letters, it is a bit hard to clearly make out); and a sales pitch from Slenderella (the voice is a British woman which makes more sense when I see that the company is in the U.K.). Here is that last recording. Here are all of the recordings. You will need to get the unzip password from for those.

It was a fun little project which reminded me of the vacuum tube days and the more formal manner people behaved in radio-like interviews in the 1950's.

Car Radio

I had noticed some detritus in the trunk of my 1995 Infiniti. Further inspection revealed that the rear speakers had deteriorated -- the cones were now isolated from the frame, suspended solely by the voicecoils. Recalling how easy it was to replace speakers in 1970's era cars, I looked to swap them out. But I couldn't figure out how to remove them! They were clearly bolted in from above but there were no screws on top to remove the grills in order to access the speaker mounting screws. I concluded that it would be necessary to actually remove the rear deck below the back window. This seemed drastically crazy, but a web search provided instructions (which didn't turn out to be precisely correct) indicating that I wasn't crazy, that deck indeed had to be removed. Didn't want to leave the car disassembled too long, so I bought replacement speakers before removing the originals and attacking the job. These are two-ohm units, and most of the ones available are four-ohms. Ironically, I found and purchased a pair of Infinity speakers for my Infiniti car. It was a bit of a job removing the top deck, but it all worked out. Got this done in March 2012 and now the bass response has returned. I guess these speakers will last the remaining lifetime of the car.

With the speaker problem fixed, I wanted to address an issue that had been gnawing at me for a while: playing MP3's in the car.

At first I had tried a Belkin FM transmitter to let an MP3 player broadcast to the car radio. It appeared to have a very low output power, because no matter what frequency I selected it seemed to heterodyne with broadcast stations as I traveled. It was too aggravating. Plus I was using the cigarette lighter socket to power it and it was more cumbersome than I'd prefer to hookup and disconnect.

With the speaker problem fixed, I wanted to address an issue that had been gnawing at me for a while: playing MP3's in the car.

At first I had tried a Belkin FM transmitter to let an MP3 player broadcast to the car radio. It appeared to have a very low output power, because no matter what frequency I selected it seemed to heterodyne with broadcast stations as I traveled. It was too aggravating. Plus I was using the cigarette lighter socket to power it and it was more cumbersome than I'd prefer to hookup and disconnect.

I had settled on using a standalone audio amplifier (abandoning the car radio altogether) -- the same one shown above in the Wire Recorder episode. Powered also through the cigarette lighter socket, it worked okay. But it still was a cumbersome connection and of course the sound was not nearly as loud as the car radio would be.

I was determined to establish a direct connection between the MP3 player and the radio's internal audio amplifier. After figuring out how to remove the surrounding dashboard cover (that houses the four accessory switches at the top of the photo) it wasn't too hard to remove the radio itself. I took the top and bottom coverplates off of the radio. Still thinking with a 70's attitude, for some reason I expected to see a stereo volume control potentiometer which would have been trivial to interrupt to divert the audio input to an external jack. But of course I knew that this radio was all digital -- the volume control is an optical encoder that drives a microcontroller. As an integrated unit I wasn't sure how I could find a place to cut the audio path. I was stymied trying to remove the circuit boards anyway: I didn't readily see how to release them (without a service book); I was afraid that I would pry something that wasn't intended to be pried and break a perfectly good radio.

There were two unused connectors on the rear of the radio. I recalled that this model had an option for a separate CD changer unit that mounts below the heating/cooling control section. There is a button on the radio to select this sound source (which did nothing at all without the changer installed). I became obsessed with using this audio path for an external MP3 player. Clearly this is the preferred method: all I should have to do is convince the radio that an external jack is a CD changer. I could connect a stereo audio input jack to the radio connectors and be done! I failed to get any specifications on the radio interface, even with the exact model number, so I attempted to reverse engineer it. How hard could that be? The radio connected to the car wiring through two plugs which were more complicated than the older simpler ones I was familiar with (power, ground, left/right speakers). I figured it would be easier to work with it in the car instead of running it on the workbench. So I made up a cable to connect to a DIN and some other type of jack on the radio, re-installed the radio and probed the signal lines with my VOM (actually DVM). There has to be a way that the external changer tells the radio that it's there. I guessed that it might ground one of those pins, so I carefully grounded each (through a resistor in case I was wrong). Pushing the radio button each time still did nothing. So I guessed that maybe a pin needed +12v instead of a ground for that purpose. Still nothing. Then thought that maybe the micro sampled those sigs on powerup; so I tried the ground and +12 on each pin (13 of them) powering down/up. Still nothing. I dragged an oscilloscope to the garage and looked at each pin while activating the radio button, looking for a pulse or something. Nada. I put a signal generator onto each pin (through an isolating cap) and found that I could drive the left and right audio paths (superimposed on the radio or CD playing). But the MP3 player's audio output on those same pins accomplished nothing -- the sig gen must have been overpowering internal circuitry. Anyway I still had the other audio source running. It killed me, but after spending a couple of days on this I had to admit defeat. I know this is the way to go, but without the radio or changer specs I could not make use of this method!!!

Back to Plan A (interrupt the audio path inside the radio somewhere and attach an external jack). Pulled the radio out and removed the covers. After about a half an hour or so I managed to remove an auxiliary board which houses the balance, fader, bass, and treble controls. The audio path has to go through here, right? Failed to identify any discernable signals. After about another half an hour or so I manage to remove the main circuit board. I was a bit terrified with this: there are a couple of flat cable connectors, I was flying blind, and feared I would break something or not be able to re-assemble properly. This radio has a built-in CD player (one disc as opposed to the 6-disc external changer) and I thought that there would be a separate CD player circuit board which had to attach to the main board. There just had to be a stereo audio path between the two! My guess was correct: there was a flat cable between the two boards with about 15 or 16 lines. By this time I had gotten the radio operating on the workbench. My plan was to interrupt the CD audio path, so I would have to play a CD while listening to MP3's. I put the boards back into the radio and good news, it still functioned. But now I had to find the left and right audio pins on the interconnecting flat cable. To get to the board pins the radio had to be upside down while playing a CD: it made a scraping sound but mostly managed to play with the anti-gravity positioning. Tadah! Found the two audio paths. Next job is to interrupt them. Removed the board again. It is a combined surface mount/through hole configuration. After some work I identified two traces I could cut to accomplish the task. With a 4-conductor + ground shield cable I routed the two audio paths through the cable to a standard stereo miniature jack with internal normally closed contacts. Routing the CD-audio through the cable/jack was not as ideal as the failed Plan B (CD changer one-way audio input) but should work fine. Reassemble everything, try with MP3 player, and it all works great! Lucky for me the audio levels were compatible as is.

It would be nice if the MP3 player's internal battery charge level were not an issue in the car. On a roll, I wanted to put a charging jack near the car radio. So I put in a 5 volt linear regulator and attached its output to a standard USB socket. I mounted it directly above the cigarette lighter but for the life of me I couldn't get to its wiring to power the regulator! Just bridged a wire onto the +12v pin on the radio connector to feed it. I could now use a standard USB cable to the MP3 player to charge it. (Two days later in the dollar store I saw a dual USB converter that plugs into the cigarette lighter socket that accomplishes the same thing -- but it is bulky and awkward compared to the jack I installed.) As a finishing touch, I made up a 6" USB cable and a 12" audio patch cable to avoid a bunch of unnecessary cabling in the cramped space.

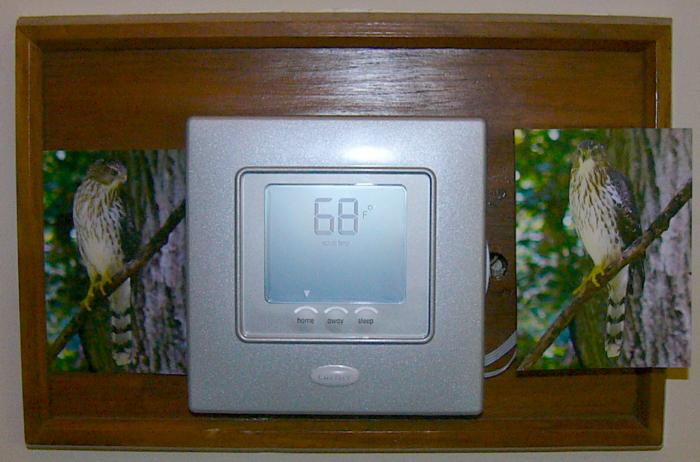

The final configuration is in the photo above. The external audio input jack and USB charging socket are just above the cigarette lighter. To play a CD I just have to unplug the audio cable from the external input jack. While I had the dashboard open I added a small piece of angle stock (painted black) to the bottom of the tray where I usually put the empty CD case for the loaded disc -- occasionally it would fall out when accelerating (nice after 17 years).